|

To pack non-free-flowing powders we offer our machines Model FFS 0520, FFS 2050 and FFS 50100 with a unique inclinated auger doser.

Our auger dosers are custom-made in-house in our factory in Shantou, China, and brought to India for installation on these machines. Since each doser is built according to the needs of the customer, we offer high-accuracy and an easy to use electronic interface. The doser uses a hi-tech stepper motor to control the dosing screw and a servo motor to operate the scraping paddle in the barrel. All contact parts are executed in stainless steel aisi 304 or 316, as required by our customer.

APPLICATIONS

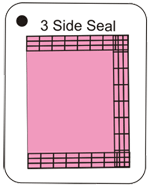

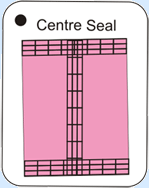

This sachet packing machine is ideal for packing spices, coffee powders, milk powder, drinks powders, pharmaceutical products, and other sticky or non-free flowing powders in 3 side seal, 4 side seal or pillow pack sachets.

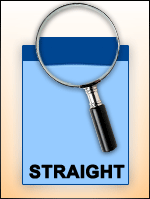

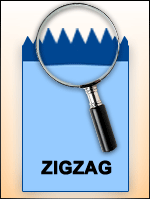

It has an extremely small foot-print. One machine requires only 10 square feet - 1 square metre of floor space. The machine has an electronic control unit for accurate sealing & cutting as per the sachet design. Sealing pattern available is 3-side seal, 4-side seal, centre seal.

Available with many optional advanced features such as microprocessor controlled sachet length, electronic speed control, automatic output sachet counting & batch creating, intelligent status warning devices for various parameters with shut-down and error reporting, etc.

COMPLIANCE WITH EUROPEAN MACHINERY DIRECTIVES

The machine displayed on this page is classified within the relevant EU directives and further conforms with the specified EU harmonized standards and in compliance with the relevant directive, the technical file of the product displayed on this page is held within the EU with our authorised representative.

|