VISIT OUR FACTORY FOR A LIVE DEMONSTRATION

|

|

State of the art:

A state of the art PLC controlled versatile fully automatic vertical form fill seal sachet packaging machine (VFFS machine) suitable for packing free-flowing granules in sachets and pouches for food & beverage, pharmaceutical, cosmetics, and other industries. The machine uses state of the art electronic motion control technology for precise multi-axis control of its various functions. The machine is ideal for tea, coffee, rice, short pasta, detergents, spices, sugar, milk powder, fruit drink, chemicals etc.

APPLICATIONS

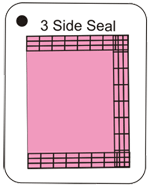

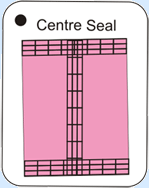

This sachet / pouch packing machine is ideal for producing standard pouches / sachets of sugar, salt, pepper, spices, coffee, tea, detergents & household cleaners, other grocery & household items, etc in convenient and economical 3-side or 4-side sachets or pillow packs, in the 20 grams to 50 grams packed weight range.

The machine has a choice of two Dosing systems:

- Advanced PLC Controlled Volumetric cup filler for granules

- Advanced PLC Controlled Auger filler for non free-flowing powders,

Advanced Volumetric Cup Filler:

The volumetric cup filler is PLC controlled and has a unique PAUSE function after every drop to ensure 100% filling accuracy at any speed.

Advanced Auger Filler:

The unique inclined auger filler is PLC controlled and can be turned around, raised and lowered, making it easy to operate, clean and maintain. It has a micro-stepping stepper motor to ensure filling accuracy.

The machine is equipped with advanced PLC Controlled features like warning device cum indicator for vertical & horizontal heaters, end of reel sensor and hopper level indicator with auto stop.

All these modern techniques make the machine ideally suitable for a wide variety of industries needing sachet packaging.

COMPLIANCE WITH EUROPEAN MACHINERY DIRECTIVES

The machine displayed on this page is classified within the relevant EU directives and further conforms with the specified EU harmonized standards and in compliance with the relevant directive, the technical file of the product displayed on this page is held within the EU with our authorised representative.

|